Why you can trust TechRadar

We spend hours testing every product or service we review, so you can be sure you’re buying the best. Find out more about how we test.

It’s great to see the arrival of the K2 Pro, a machine that, while not officially the replacement for the K1C, seems to be in all but name, along with the smaller K2. The K2 is actually more in line with the size of the K1C, however, specifications, features, and the advancement in technology really sit this new Pro version at the level the K1C was when that first launched, and will appeal to those K1 C owners as a viable update.

The new machine is a high-end enthusiast model in the new K2 range, which sees the K2 Plus that I looked at back in March with its 350 × 350 × 350 mm build area, and the newly released K2 with its 250 × 250 × 250 mm build volume.

This brings the present K2 line-up to three machines with plenty to offer for all budgets, and offering users stepping up from open-frame designs to these more professional fully enclosed units plenty of options.

One of the big changes since the release of the K1C is that now most machines are able to print with specialist material filaments out of the box, and it was really the Elegoo Centauri Carbon that changed things, makingcarbon printing possible without hoitend upgrade at a cheap price.

The K1C had, until recently, also been used as one of my benchmark machines by which all others are measured, and that machine was finally retired last month after a solid couple of years’ use.

Against some of the best 3D printers, the K2 Pro then has a great deal to live up to, and as the middle machine, it’s going to be the one that everyone is looking at. Checking over the machine, specifications and features, everything you’d want from a 3D printer in autumn 2025 is here: multicolour printing, heated chamber, wireless printing, carbon and specialist material support, and if the print quality is anything like the previous iterations, then we could have yet another printer of exceptional quality to choose from.

Creality K2 Pro: Design

When the original K1 Series arrived, it was a huge evolution of design for Creality as the open-frame printers made way for the fully enclosed, which offer far better and greater material support. The one issue with the K1 series was that there was no multifilament option, and at the time, with the Bambu Lab machines arriving on the scene, the spotlight which should have been beaming directly down on the K1s, especially the K1C, was snatched away to the X1C and the potential of multifilament printing.

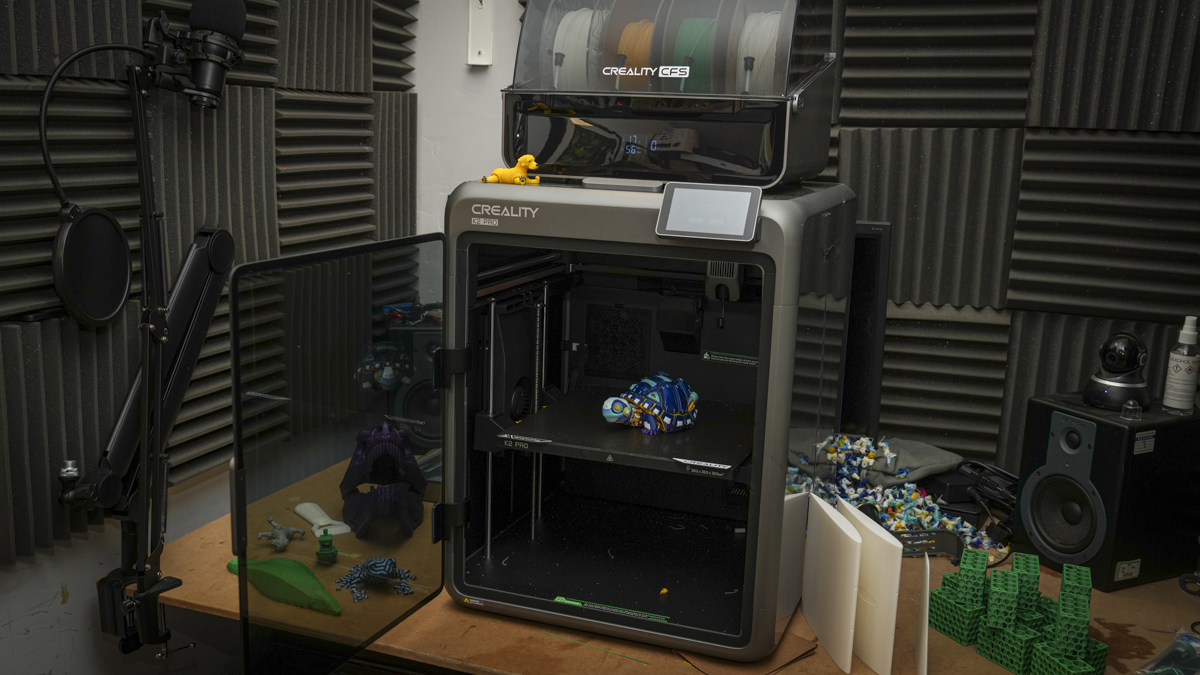

After several successful open-framed multifilament machines and the K2 Plus, the K2 Pro has arrived, again supporting Creality’s CFS module that enables four-colour printing out of the box, and up to 16 colours with additional units. The K2 Pro seems to measure up very nicely.

The design has been overhauled across the entire K2 line over the K1 series, everything has become more refined and product-designed. The smaller K2 is closer in size to the K1C, however, as everyone is now wanting larger, this middle-size machine will inevitably be the best fit.

When it comes to the size and weight, there’s nothing small about the K2 Pro, unless of course you compare it to the huge K2 Plus. At 455 × 477 × 573 mm and weighing in at 23.7 kg, it is a sizable machine.

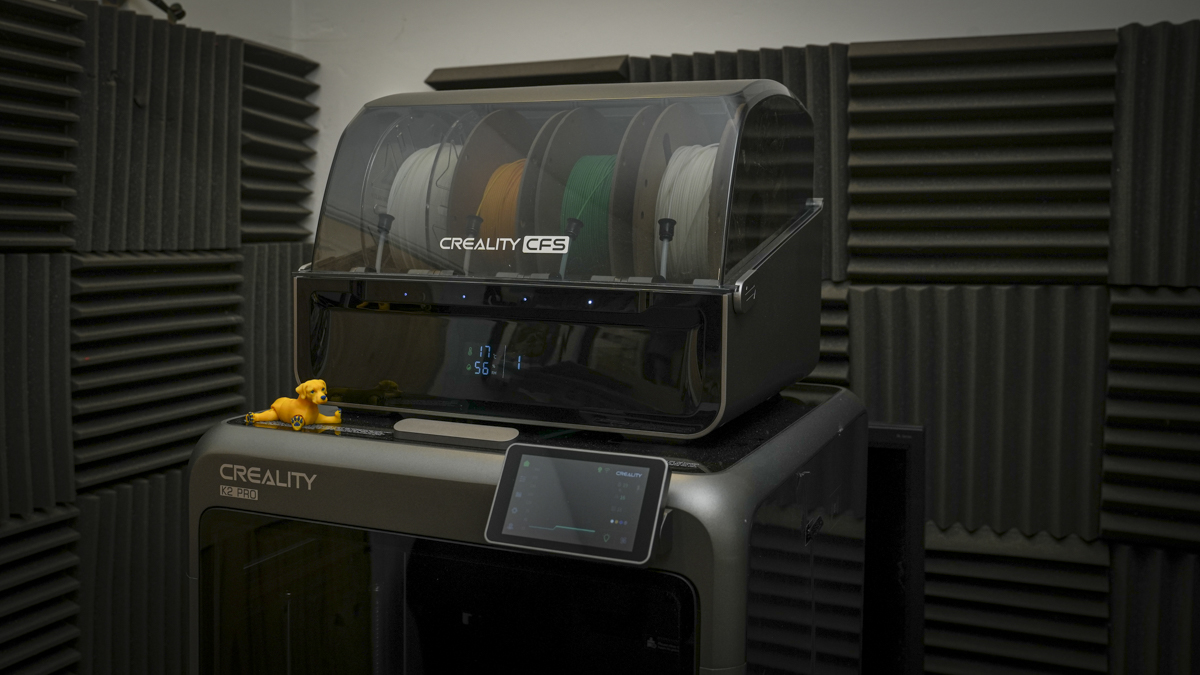

As with other fully enclosed machines, there’s a glass lift-off lid where the CFS can sit if you have the combo version. Then filament from the CFS is fed through a single tube from the back into the machine buffer and into the tool head via tubing. There’s also a data cable that runs from the machine to the CFS for communication and power. This means that the K2 Pro Combo only requires one AC socket to power everything, unlike some other machines that require one for the machine and another for the CFS or equivalent.

On the front of the machine, there’s a glass door effectively sealing the inner chamber and enabling the active heating for specialist materials. Again, it’s all well thought through, and the differences between the K2, K2 Pro and K2 Plus really do come down to size.

Again like the K2 Plus, the touchscreen interface mounted on the front enables direct interaction with the machine, and for the most part this is fast and responsive. Although, through the test, there were a few occasions with larger files where the responses from the machine weren’t quite as fast as I would have expected. However, it did seem reliable and that delay was never more than a second or two.

While the design is extremely well thought through and looks great, there are a couple of features that I would have liked to have seen. Firstly, an automatic venting or cooling option, as you still need to leave the front door ajar when using PLA. The likes of the Bambu Lab H2S series, admittedly much more expensive, feature auto venting, and the Original Prusa One even features a manual top vent for this reason.

Then, as with most of these multifilament printers, there is the issue of waste, and here again the volume of filament that fires out the back is excessive, with no form of collection readily available. With the size of the machine, it can then make it a little tricky to clean up around the back.

Creality K2 Pro: Features

To stay relevant in multifilament 3D printing, a new machine needs to be exceptional when it comes to print quality but also innovative. Here, with the Creality K2 Pro, it strikes a tried and tested balance that focuses on print quality and refinement over anything new.

This is a machine that will sit perfectly in design studios, classrooms and workshops, used for reliability and print quality rather than must-have innovation.

In this review, I’ve looked at the Combo version of the machine, which essentially means it arrives with the CFS that enables multicolour 3D printing. The CFS, filament box is of a great design and, like the machine, offers an active heated chamber that ensures your filament is in the best possible condition before it enters the machine. The base unit will enable up to four colours; however, at around £150/$150, you can add another to enable up to 16-colour printing.

Another quick point on the CFS: it has been RFID-enabled and will recognise Creality RFID reels, which then helps to set up the correct temperatures and flow for each filament. One of the other features here is the filament relay, this means that if you have two identical RFID filaments in the CFS and one runs out during printing, then the machine will automatically swap.

The CFS also features a spring-loaded filament guard that prevents filament from jumping out of its position. This is actually quite a common issue, and if a jam is detected, the machine will automatically pause proceedings until the issue is resolved.

One of the big features with this machine, aside from the multifilament printing, is the heated chamber. This takes the machine up another level from the K1 series and enables the printing of specialist materials such as Nylon and ABS. Essentially, the heated chamber sets perfect conditions for these materials and means that they’re less likely to warp. It does, however, also mean that for PLA and similar materials, you need to leave the door ajar to enable airflow.

The feature that makes me compare the K2 Pro against the K1C rather than the standard K2 is the size. While the K2 is closer, most users’ aspirations have grown since the release of the K1C, and this larger middle machine with the 300 × 300 × 300 mm platform just seems to be a great print bed size for the majority of uses.

Auto-levelling has come on leaps and bounds, and this is one area of real innovation for this machine. Rather than auto-levelling the entire platform like most machines, it just checks the area where the model will be printed. This might seem like a small feature, but the reduction in time to do the checks before printing shaves a few minutes off the overall print times.

Another issue I’ve had with some printers is using other manufacturers’ filament in the machine, flow rates not keeping up with the action, etc. However, with dual AI cameras that monitor the print process, the K2 Pro joins only a couple of other machines in not having any spaghetti or platform release issues. Through this test, the machine has printed for well over 100 hours and gone through a few kilos of filament to check reliability, so on this front it really excels.

Specs

Print Technology: Fused Deposition Modelling (FDM)

Build Area: 300 × 300 × 300 mm

Minimum Layer Resolution: 0.05 mm

Maximum Layer Resolution: 0.30 mm

Dimensions: 445 × 505 × 850 mm

Weight: 23.7 kg

Bed: Heated bed, up to 110 °C

Print Surface: Flexible PEI build plate

Software: Creality Print 6.0 (or newer)

Materials: PLA, PETG, PET, ABS, ASA, PLA-CF, PA-CF, PPA-CF

Print Speed: Up to 600 mm/s (with acceleration up to 20,000 mm/s²)

At the heart of the machine is the new tool head with direct drive extruders. Through the test, this impressed, handling all filament with ease. These tool heads are getting more complex, and the K2 Pro’s features a sensorised filament path that detects issues including filament runout, highly accurate in/out sensors and a magnetic cutter.

Like most machines now, it also features an easy-swap hotend, so if the worst does happen it should only take a couple of minutes to pop in a new one.

The tool head also features a nozzle AI camera that monitors the flow and will automatically adjust the pressure advance, flow rate and waste chute blockages.

The machine is backed up by the fantastic Creality Print, which is of course based on PrusaSlicer, which has become the standard for the majority of 3D print manufacturers.

Creality K2 Pro: Performance

The K1C has been one of my test machines since it was launched. Now, the K2 Pro, while larger than the K1 C, fills that gap, it would be the standard K2 as it’s closer in size, however with advancement of time and expectations that we now have of 3D printers, the K2 Pro just feels like a better fit.

Before delving into the performance, the 300 × 300 × 300 mm build area is the sweet spot for this style of machine. It’s essentially large enough to operate small production runs, and if you want to print a wearable helmet for cosplay, then this is an ideal size.

Creality has produced a machine that really refines the design, and there’s plenty here to like, especially as you start to look into the design and just how robust it is. Firstly, the full metal and glass construction is premium, and as you look into the interior, the use of linear rods and rails means the movement of the build platform and tool head is tight and precise.

Even when printing at full speed with the initial 3D Benchy tests, the machine sits rock solid on the work surface. There’s no wobble due to the weight and strength of construction, and checking over the prints, the filament colour is consistent along with the surface texture. It’s all exceptionally well refined.

Getting started with the machine was all easy enough, and Creality knows how to make a machine that is essentially almost ready to go. It actually took more time to strip away the packaging than it did to prepare the machine, and after the initial checks, which do take some time, the 3D printer was ready to start a few prints.

It was instantly apparent that the speed of the machine was exceptional, and while other machines match the speed, the quality of the prints it was producing just seemed to be consistent and a step up from most other printers in this price range. For most prints, the default settings of 300 mm/s for the inner walls and 200 mm/s for the outer produced decent results. Even taking this speed up to 600 mm/s to print 3D Benchy produced a relatively decent print, taking 22 minutes for the full 3D Benchy print.

One of the aspects that helped with the print speed was that the auto-bed levelling was only applied to the area where the print was being laid. For 3D Benchy, this cut minutes off the print time.

One issue I did have with Creality Print is that the layout of the application has changed a bit from the standard PrusaSlicer, and as such, some features are a little difficult to pinpoint. Also, when you click the objects, it’s not instantly apparent where the relative settings are.

Essentially, everything has shifted from the left of the screen to the right, and once you do find the access, there are plenty of options available for the general user, although advanced users may quibble about some of the more advanced options.

Through the test, I ran a series of different filaments through the machine, starting with PLA and ABS to test standard and specialist materials. Both printed with exceptional quality, as the print benchmark highlights.

As I moved on to some of the more specialist materials, again the printer performed well, and the drybox CFS handled carbon-fill filament without issue. TPU, on the other hand, I fed through as an external filament, disconnecting the CFS so it could utilise the direct feed, but again, the results were impressive.

The new build and design of the printer really do help ensure a solid print experience, and the K2 Pro in this respect is just about as refined as any, capable 3D printer and produces outstanding prints in a variety of materials for engineering, prototypes and, of course, fun.

The CFS obviously takes on the ability to run multicolour prints, and again the speed and precision really stand out. To be honest, after looking at the budget-end Creality Hi, it would have been a surprise if the print quality wasn’t exceptional for one of the companies more premium machines.

The multicolour printing is, of course, slower than you would expect with single filament machines, but it does keep up the pace. However, with the Snapmaker U1 arrival, this machine has essentially once again changed the market, while the quality and speed of the K2 Pro is good, it’s way behind what is now possible with that other machine. You also have the subject of waste to consider, and once again piles of filament do stack up behind the machine.

Still, that said, it’s only due to recent releases that the filament waste and speed of change between filaments is highlighted as an issue, and in reality, the quality of the end product is what counts.

The end print is exceptionally good, and what stands out about the prints more than anything else was the consistency of the quality.

Creality K2 Pro: Print quality

Dimensional Accuracy: Score of 3

Target 25: X: 24.75 mm / 0.25 mm error | Y: 24.79 mm / 0.21 mm error

Target 20: X: 19.84 mm / 0.16 mm error | Y: 19.71 mm / 0.29 mm error

Target 15: X: 14.83 mm / 0.17 mm error | Y: 14.81 mm / 0.19 mm error

Target 10: X: 9.77 mm / 0.23 mm error | Y: 9.75 mm / 0.25 mm error

Target 5: X: 4.88 mm / 0.12 mm error | Y: 4.74 mm / 0.26 mm error

X Error Average: 0.186 mm

Y Error Average: 0.240 mm

X & Y Error Average: 0.213 mm

Fine Flow Control: Score of 5

Fine Negative Features: Score of 5

Overhangs: Score of 5

Bridging: Score of 5

XY Resonance: Score of 2.5

Z-Axis Alignment: Score of 2.5

Final Score: 28 out of 30

Creality K2 Pro: Final verdict

This is a tough one, as the Creality K2 Pro is an exceptional machine capable of producing some of the best 3D prints of any machine in this price bracket. It also looks great, and the overall build quality and mechanics, as well as the serviceability of the machine, mean that it should give you many years of use.

The advancements of the technology compared with the K1C are extensive, and looking back at what was, in the K1 C, a cutting-edge machine at the time of its release, it’s amazing now to see just how much has developed in a seemingly small amount of time.

However, there’s also the subject of the competition, especially the likes of Snapmaker, who up until now have carved their own niche with their multitool machines. However, the Snapmaker U1 has changed the outlook, especially when it comes to speed and waste.

There is just no comparison, although that machine at present is realistically only good for the likes of PLA and materials that can be used in an open-frame environment.

This still gives the K2 Pro a market and, while you may not get the speed for multicolour and you will produce more waste, when it comes to outright quality of prints and reliability, there is just no doubting how good this machine is.

Then there’s the print volume with that 300 × 300 × 300 mm sweet spot, and the heated chamber that gives you access to printing a huge variety of materials. These advantages still give this machine an edge for higher-end enthusiast and professional use.

Then, of course, if you have a Creality machine, this is the natural upgrade, and it comes with the quality that we have now come to associate with the brand.

Ultimately, the K2 Pro is one of the most refined and solid 3D printers on the market at present, and if reliability and print quality is key, then this is a great option.

Should I buy the Creality K2 Pro 3D printer?

Buy it if…

Don’t buy it if…

For more crafting tech, I’ve tested out the best laser engravers.